Two Books and an Invitation to Learn about Systems Thinking

This year, I invite you to read two books with me: The Fifth Discipline by Peter Senge and The Toyota Way to Service Excellence by Jeffrey Liker. As I started reading the Fifth Discipline, I remembered how Liker’s work helps us put Systems Thinking in practice through Lean Thinking.

Together, these books answer two fundamental questions:

- Why is the Fifth Discipline relevant today?

- Why do we need a systems thinking approach in our organizations?

Why Systems Thinking Matters

We tend to focus on what we have to do, our tasks, our roles, our metrics. What’s difficult is seeing how our actions affect others. Even harder it is to see that those effects loop back and impact us.

This is where systems thinking becomes essential. As Senge reminds us: You can only understand systems by contemplating the whole, not by analyzing its parts in isolation.

What do we mean by a System?

Let’s start by understanding what we mean by a system in Systems Thinking. A system can mean many things, a business, a school, a university, a team, or even a rainstorm system, a production line, or a healthcare system.

So if we take an organization as a system, we can use Systems Thinking as a way of looking at it differently: looking at the actions and interactions, not as isolated parts of the system, but as interrelated, how they work together, and how they impact each other. Systems Thinking helps us see how our own actions create the problems we experience and how to make changes.

This shift in perspective allows us to stop reacting to symptoms and start addressing root causes.

From Systems Thinking to Learning Organizations

When an organization consistently applies Systems Thinking and all its best practices, tools and disciplines, it becomes what Senge calls a Learning Organization.

I love this term because it represents an organization that is:

- Always in the state of learning

- Continually expanding its capacity to create its future

- Willing to reflect, adapt and evolve

However, many organizations struggle to become learning organizations because of what is called learning disabilities.

Common Learning Disabilities

Peter Senge identified several patterns that prevent organizations to recognize threats to their growth, understand the implications of those threats or come up with alternatives to change:

I am my position: When people focus only on their role, they don’t see how their own actions extend beyond that role and they feel little sense of responsibility for overall outcomes.

The illusion of taking charge: When organizations respond to issues only reacting to events, they miss the long-term patterns that drive those events and fail to address the root causes of these patterns.

The parable of the boiled frog: When organizations are set up to react to sudden changes, they miss slow, gradual changes that pose the greatest threats over time.

The delusion of learning from experience: When the negative effects of their actions happen elsewhere, teams fail to connect cause and effect across functional boundaries.

A Simple Example: A School as a System

Imagine a school system. Your child tells you that teachers sometimes come unprepared for their lessons. For instance, your child detects a wrong question in an exam and after 20 minutes lost, the teacher asks the kids to skip it. Week after week, hearing other situations, your concern grows. You contact the school principal. To your surprise, the principal cuts you off when you’re explaining and tells you to talk to the teachers directly (“This is not my position”) and highlights that these are their best teachers (“Surely, there is nothing wrong here, the enemy is out there”). You keep hearing more cases from your child and similar impressions from other parents. Unfortunately, the consequences are not going to show up immediately (“The parable of the boiled frog”), but years later, when enrollment declines and trust is lost.

Systems Thinking

What we want to do is to watch out for those behaviours, and solve them with a new way of thinking. But, Systems Thinking alone is not enough to help us become a learning organization. That’s why Peter Senge calls it the Fifth Discipline, it needs to be integrated with other disciplines. Systems Thinking also needs teams willing to:

-

Build a shared vision, a picture of the future that we want to create together. Here, there is an important distinction, we’re looking to build a vision that fosters commitment rather than compliance.

-

Look inward, being open to challenge our assumptions and identify shortcomings in our present ways of working (understanding our mental models).

-

Be made up of lifelong learners, committed to our personal mastery

-

Learn as a team so we have the skills to learn with each other and innovate.

-

See actions, events, behaviors as systems, interconnected, looking at the larger picture and how we interact beyond individual perspectives, and understand end-to-end processes deeply, looking for the root causes of behaviors so we can change them.

Where Lean Thinking Comes In

As we learn and practice Systems Thinking, we can see important concepts from Lean Thinking:

-

Train and develop people through repeated practice, challenge people to do their best as an individual and as a team,

-

Question our assumptions and look for the root cause of problems,

-

Analyze end-to-end processes looking for wastes and variation

-

Improve continuously in pursuit of customer value.

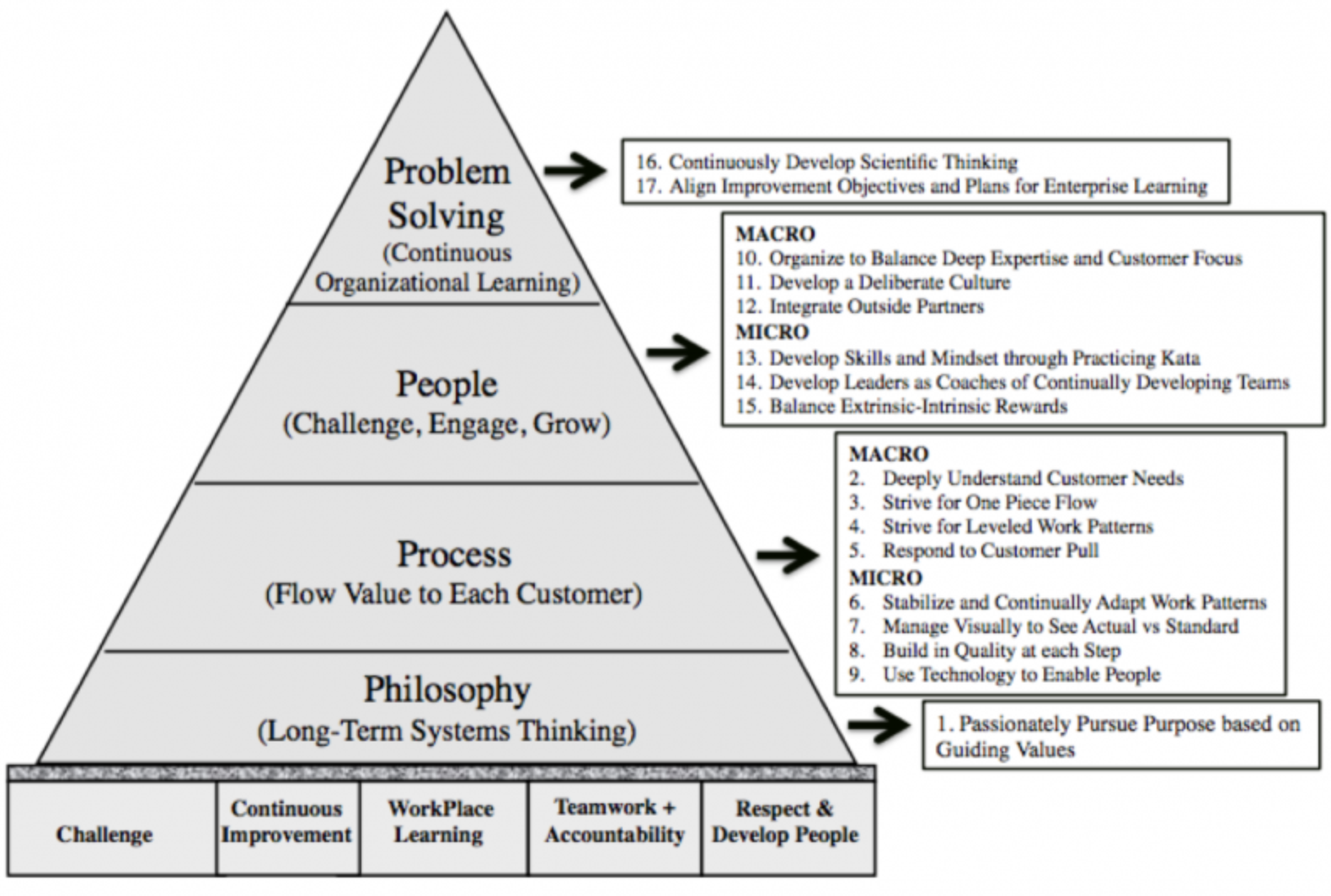

Image from The Toyota Way to Service Excellence by Jeffrey Liker and Karyh Ross available at the Liker Lean Advisors website.

To help organizations get started, Liker proposes a practical model focused on philosophy, process, people and problem solving. If I were to summarize it, I would highlight two essential points:

Think long-term. Not surprisingly, adopt a long-term systems thinking approach that connects processes, people and problem solving in one coherent strategy, creating a culture that challenges people to learn and grow.

Design your business processes. Start with a high-level understanding of customer needs: what they want, how much and when. Design key processes to achieve these goals, then move into detailed design, where the heavy lifting of continuous improvement happens through experimentation, learning and refinement by the people doing the work.

Conclusion

There isn’t a recipe to be copied and it’s challenging to apply Systems Thinking in practice. But we’re on the right path when we intentionally design processes, observe how they behave, and continually refine them to deliver the services that our customers want.

So, I’ll leave you with a few questions:

- Where are you in this process?

- How does your organization learn?

- What’s one small experiment you could run to strengthen Systems Thinking?

Key Concepts

- Lean means doing more with less, like a professional athlete.

- Continuous Improvement means that we’re constantly challending the way we work to find a better way.

- Kaizen means “change for the better”, systematically working toward overcoming obstacle after obstacle one at a time, experimenting and learning from each experiment.

- Waste is anything that causes deviation from the “perfect” process: a process, without interruptions, that gives the customer exactly what they want, in the amount they want, when they want it.

- Jidoka is a pillar of the Toyota Production System to stop when there is a quality problem and immediately solve the problem.

- Gemba is where the work is done, where we can observe the reality.

- Just-in-Time means “the right part at the right time in the right amount”.

- Built-in Quality is when quality is integrated in every step of a process to prevent defects, not only at the end.

- Takt is the rate of customer demand.

- One-piece flow is that “perfect” process where each step does what it is supposed to do without waste. We can recognize that there is no perfect process, but we’re always striving to achieve it.

Recent Posts

-

Books I read in 2025

-

Designing Agentic Systems with People in Mind

-

Using a Process Mindset to Drive Innovation with Agentic AI

-

Is Generative AI Weakening Our Critical Thinking?

-

Embracing the AI Shift: Copilot and the New Era of Work

-

Product Owner and Process Engineer

-

What I read in 2024

-

The Science of Choice

-

Rolling out Enterprise Architecture

-

7 Steps to Create Processes

-

First thoughts on Prediction Machines

-

The woman I am

-

Becoming a Runner

-

Business Process Overview